Smart factory mobile production line solution

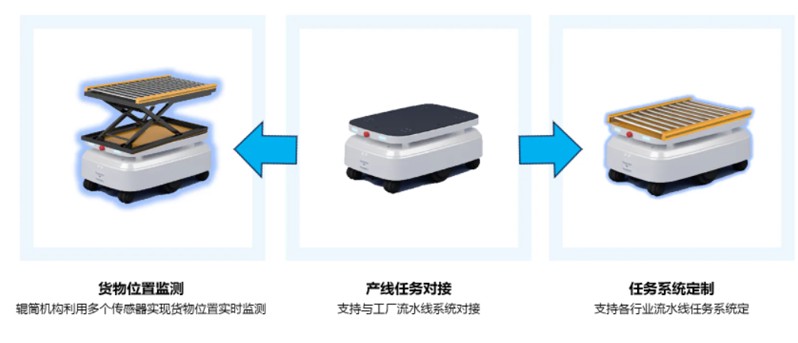

Roller simple composite transport robot can meet the needs of internal logistics rapid transit, according to the industry process, flexible integration of different functional modules can be connected with the automated assembly line, roller simple conveyor line, to achieve flexible material handling and docking between the assembly line, suitable for factory logistics automation conveying field, support multiple types of material transportation, such as pallet materials, carton materials, etc. Significantly improve workshop logistics efficiency.

Application range of roller and simple composite transport robot

Logistics e-commerce, 3C electronics, precision instruments, traditional manufacturing

Roller composite robot

Upper drum assembly drive, can be connected with AMR to transfer goods, to the production line, to achieve material and production line connection, taking into account the material box, Tray tray, pallet and other different vehicles, support cross-floor handling connection

R100 products are mainly to realize the docking of robots with machines, transmission lines or tooling mechanisms, connecting vehicles or materials, so as to meet the intelligent production of the factory, and optimize the design of vehicle safety obstacle avoidance, docking confirmation and material testing

Custom development of composite robot

The specific form needs to be determined by combining the height of the production line and the shape of the goods

Automatic Transport Robot Scheduling Control System (RCS)

Through the control and scheduling of robots, the RCS robot scheduling control system realizes the automation of raw materials, semi-finished products and finished products between production lines and production lines, between production lines and warehouses, and in warehouses, reducing labor costs and improving work efficiency.

AutoXing-Dev-RCS scheduling

Intelligently adjust the queuing strategy of the robot to shorten the task waiting time;

Analyze and predict the time for the workbench to generate tasks

Schedule idle mobile robots to wait at the task point in advance to improve the overall logistics efficiency;

Reasonable control of the shelf handling sequence and timing, to achieve the task load balance of each workbench.

Robot local scheduling/support for external device interconnection

Without setting up RCS, it can realize multi-machine cooperative work, and realize common scenario functions such as multi-machine encounter avoidance, narrow lane scheduling and ladder scheduling. Rapid deployment landing, flexible access to the delivery line.

Gate machine, automatic door, rolling door market 99% passenger elevator, freight elevator, support multi-machine ladder scheduling arrival notification light, notification sound