Basic function: Load/lift (optional)

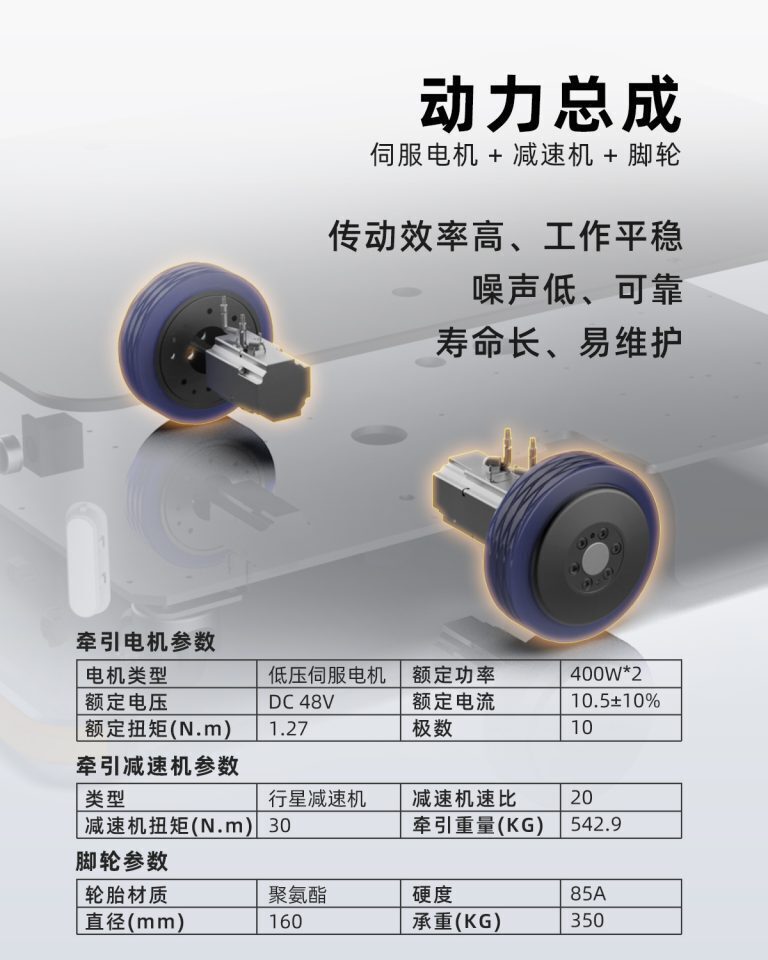

Drive mode: Powertrain (servo motor + reducer + caster)

Path type: single line; The loop line; Fork in the road

Load weight: ≤600kg

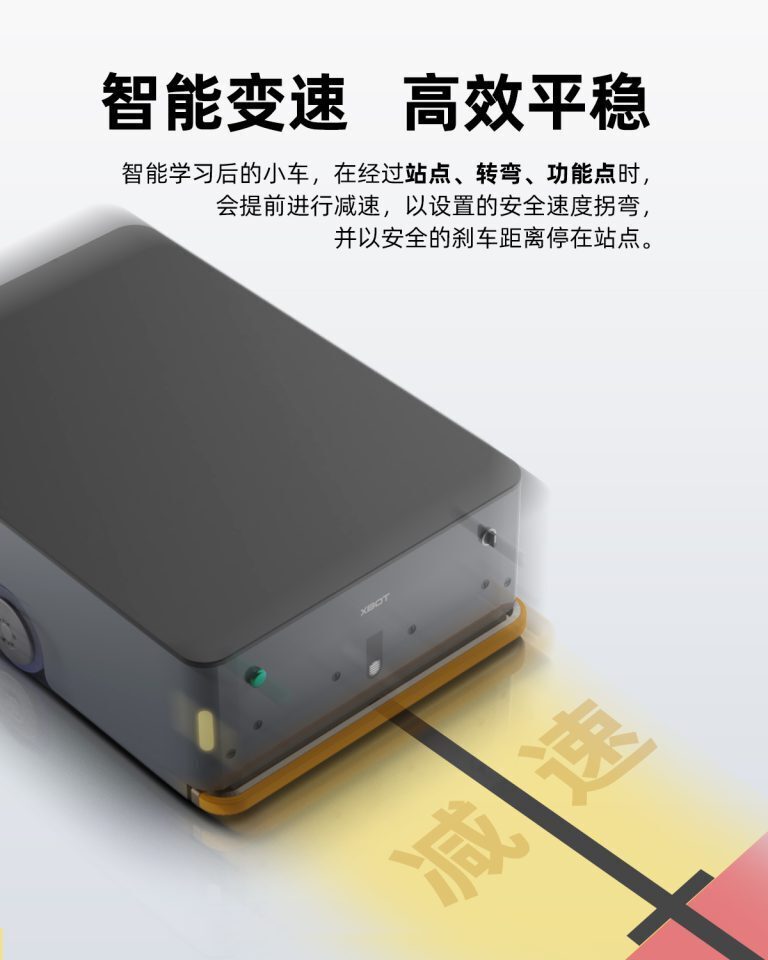

Operating speed: 0.5-4km/h

Stop time: 1 second -40 minutes

Minimum turning radius: 1.3m/right-angle turn

Stop accuracy: +10mm

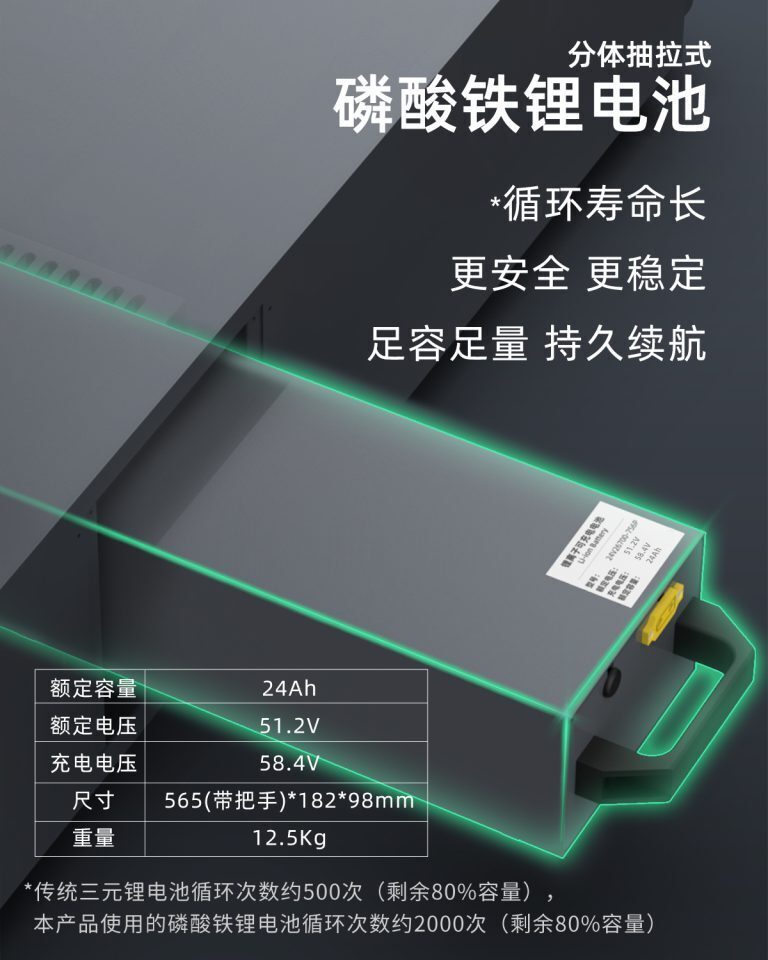

Battery capacity: DC 51.2V 24AH lithium iron phosphate battery

Full load operation time: about 20 hours

Average charging time: 4-6 hours

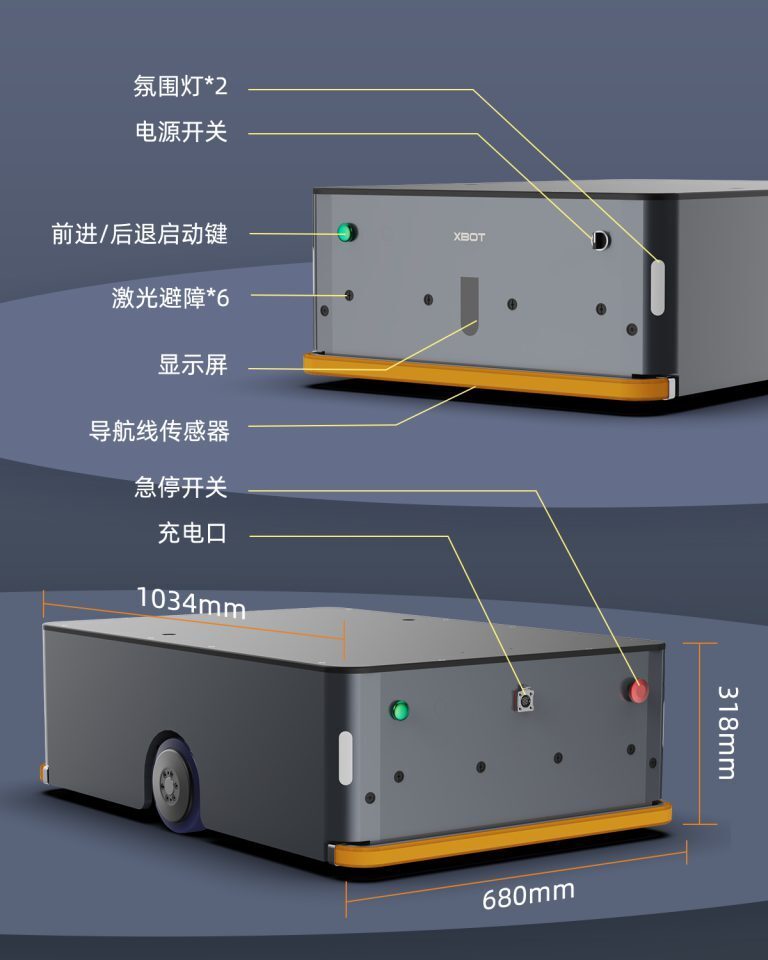

Body size: 680mm*1034mm*318mm

Body weight: 130kg

Body weight :130kg

Lifting stroke :50mm

Obstacle detection: laser obstacle avoidance sensor; Collision stop

Return mode: automatic/manual, manual bidirectional start; Run forward, run backward

Charging mode: direct charge/external charge; Optional wireless charging 10A

Charging voltage :AC220V--DC56V 4.5A

Audible and visual warning: Tape

Standard accessories: magnetic strip 20 meters, 1 charger, manual, certificate

Magnetic strip parameters: smooth N pole, adhesive S pole; Thickness 1.2mm* Width 30mm

AGV industrial distribution robot 600KG version

Standard Edition:

Single line, loop line, multiple stops can be stopped in the middle (all stops in turn),APP can adjust the driving speed, turning speed, deceleration line speed, support manual button start/timing automatic start two modes

Remote control version

Includes standard edition features; Remote control forward, backward, stop; Or optional USB to 433 RF, send instructions through the computer control.

Site editing

Includes standard Edition features

You can edit the site in the mobile APP, set different residence times for each sub-site, and run forward and reverse.

Site call (15 key remote control)

Includes standard version, site editing function, can be switched through the APP; 15-key remote control: After learning the route, the number of each station and the number key of the remote control are paired and combined, and the station can be designated by the 15-key remote control; Task mode: Multiple task instructions can be freely edited through the APP, and the car runs automatically according to the task instruction cycle.

Site call (USB to 433)

Replace 15-key remote control with USB to 433 remote control, and send site instructions directly through the serial port of the computer.

RS485 Serial communication (wired and wireless)

Includes standard version, site editing, site call function; The computer/host computer /PLC interacts with the AGV through wired or wireless RS485 communication;

Basic version: forward, backward, stop, speed instructions; Multi-station positioning: includes the basic version of the function, can specify the car to reach the destination station through each sub-station instruction; The current status information of the car can be obtained by automatic feedback of the car at fixed time and active inquiry of the host computer.

Trackless operation (Handheld Bluetooth remote control)

Includes standard edition features; Handheld Bluetooth remote control, trackless operation, remote control acceleration and deceleration, cruise; Get off the rails and let the car do what it wants.

Bifurcation function (RS485 serial communication)

Single line, branch road line, can be set up multiple stops; 15 key remote control /485 mode, task mode can be switched in the APP; 15-key remote control /485 mode: After learning the route, you can specify the station stop through the multi-key remote control/sub-station RS485 command. Task mode: Multiple task instructions can be freely edited through the APP, and the car runs automatically according to the task instruction cycle.

Lift function (used with AGV)

The lifting control mode can be divided into the following three types according to the selection of AGV:

1. Manual mode: body lifting button/remote control lifting button.

2. Automatic mode: In task mode, multiple task instructions can be freely edited. Sub-station residence time, lift/fall action setting, car automatic cycle execution

3. Manual + automatic mode: The car can be manually controlled to reach the specified station through the 15-key remote control, and the car can automatically read the lift/fall command of the station in task mode.

* Optional RS485 model, can be controlled by command lifting.